About Us

About Us

Holland Manufacturing

Since our establishment in 1973, Holland’s unwavering commitment to delivering top-quality refractory shapes has remained ingrained in us. This commitment is the foundation of our culture to produce nothing but the best.

First and foremost, at Holland, we specialize in providing engineered solutions tailored to your specific requirements. Other suppliers may attempt to retrofit their standard products to fit your needs. Instead, we focus on custom solutions, crafting solutions engineered to fit your needs for optimal part performance from inception.

Supporting our manufacturing process is a hands-on customer service approach. We engage in active listening to understand your requirements, ask relevant questions, and tailor the highest-performing shapes for your operations. Primarily, we perceive our customer relationships as partnerships, ensuring all products adhere precisely to your specifications, while maintaining an open attitude towards adjusting product structures when needed.

Our pride in craftsmanship resonates throughout our daily operations, evidenced by our dedicated team members who continuously strive for improvement, collectively enhancing everything we do.

Experience the Holland Manufacturing Difference And Entrust Us With Your Most Intricate Part Requirements

A Company History of Family Traditions

1973

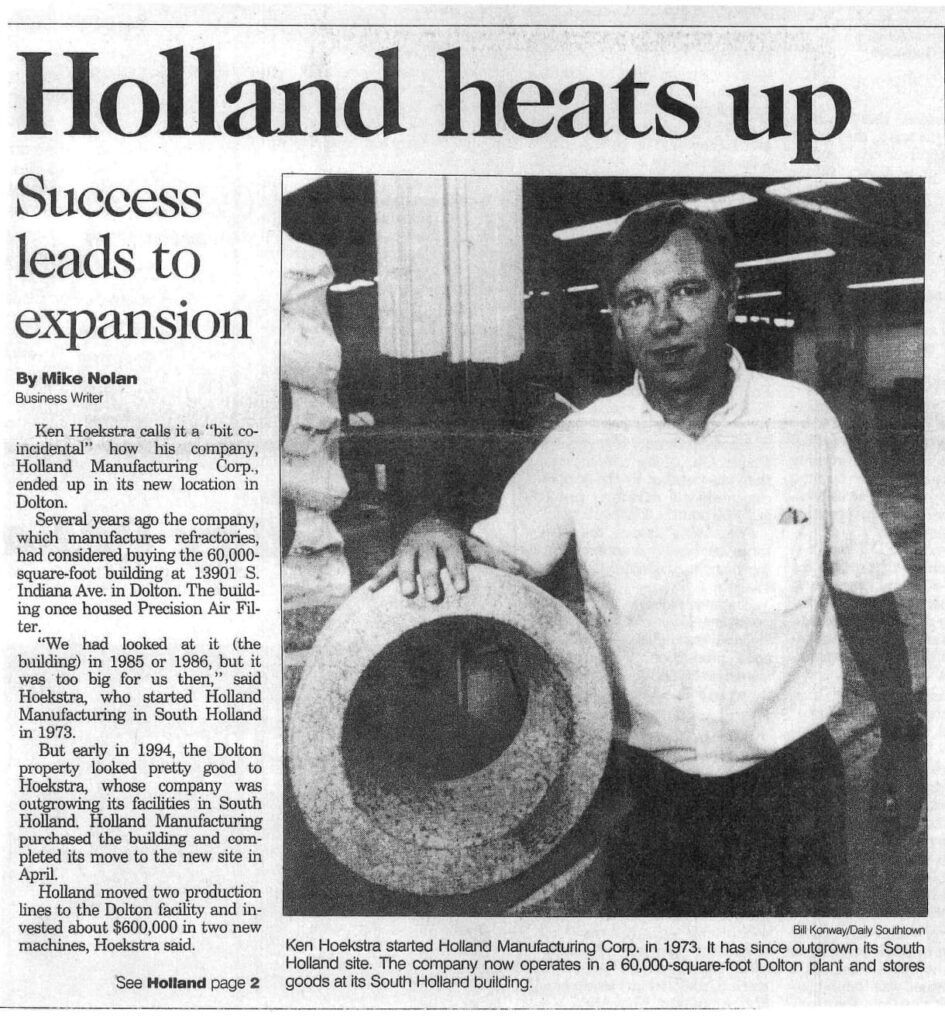

Established on October 19, 1973, Ken Hoekstra embarked on a journey marked by innovation, resilience, and unwavering commitment to excellence.

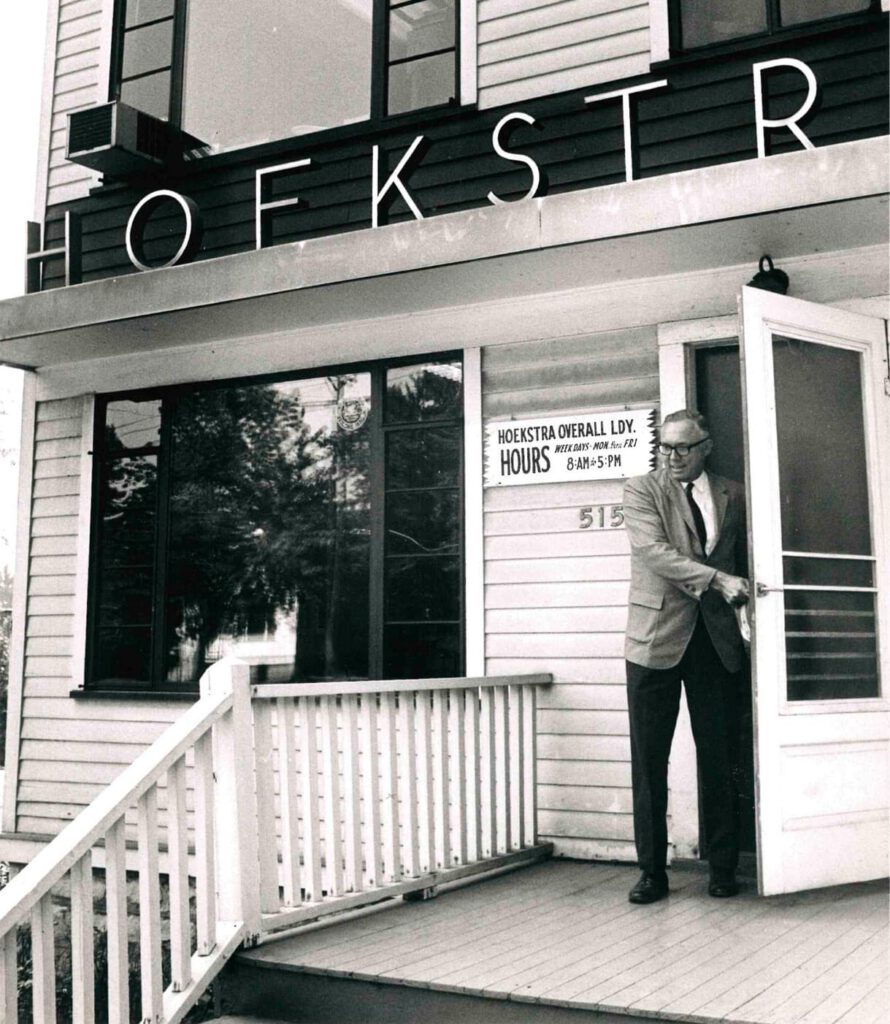

The roots of our company trace back to a humble beginning, as our founder, inspired by familial legacy, set up the first shop in the building formerly owned by his father’s laundry company, Hoekstra Uniform Cleaning. This symbolic transition laid the foundation for a new business organization. Our early start focused on manufacturing small supply items for the foundry industry.

1985

In the 1980’s, as Holland Manufacturing continued on a growth path, observations and a solid understanding of market trends showed that the steel industry was in need of quality refractory shapes. The drive to fill this need fueled the expansion of our manufacturing operation to begin producing a large array of refractory shapes. During this time frame, Holland secured a patent for a pressing process capable of producing large, high and uniform density shapes. The steel industry was the target market. Later industrial applications in non-ferrous industries were developed with great success.

1994

In a milestone move reflective of our expanding operations, we relocated to our current facility on April 1, 1994, signaling a new chapter in our company’s evolution. It was during this time that we laid the groundwork for future advancements, breaking ground for the construction of a Bickley kiln, a testament to our commitment to cutting-edge technology and superior craftsmanship.

2000

Throughout the 1990s, our journey of innovation continued unabated. We devoted ourselves to the development of groundbreaking processes aimed at enhancing the performance and durability of our products. The culmination of this effort was the introduction of the revolutionary Cryocast process in 2000, later refined and perfected into what is now known as the ISO-Tuff process, setting a new standard of excellence in the industry.

2012

In 2012 and 2013, we made the decision to enter into the glass industry and swiftly established ourselves as worthy pioneers in the field. Our products garnered acclaim for their unparalleled quality and performance, underscoring our unwavering commitment to exceeding customer expectations.

2016

The dawn of a new era arrived in 2016 with the installation of the first CNC machines to create our own in-house machine shop. This investment enabled us to produce the precision machined mold tooling that is required for our manufacturing processes, instead of relying on outside machine shops. This also allowed us to improve the lead-time for new products and gave us the opportunity to quote, design, and produce more complex products. This technological advancement continued in 2017 and 2023, with further additions of new and more advanced machinery.

Ken has been joined by daughters Rebecca Hoekstra and Jennifer Bezenah. This next generation of leadership has already been proven as they have driven significant growth over the last five years, expanding on the legacy of the family-owned company.

2023

As we celebrated our 50th anniversary in 2023, we reflected on our history and celebrated the milestones and achievements that have shaped our journey. Yet, true to our ethos of continual improvement, we remain focused on the future, poised for even greater accomplishments.

Also in 2023, we saw a new chapter in the business with the company’s expansion into Latin America, with sales based out of Colombia, South America. Today we are delivering shapes throughout all Latin American countries with rave reviews from our newest customer relationships.

2024

In 2024, a new Bickley kiln commenced operations, expanding our manufacturing capacity and improving delivery timelines. As we look ahead, we remain steadfast in our commitment to pushing the boundaries of excellent customer service, delivering superior products, and pioneering innovative solutions to meet the needs of our customers and the industry as a whole.