Chemical

Tailored To Suit Your Requirements And Enhance Productivity

Chemical

Holland’s precision machined mold tooling, proprietary ISO-Tuff injection process, and unwavering commitment to quality enable us to produce complex shapes with high densities that conform to the tight specifications of the chemical industry. Engineered with premium raw materials, our refractory shapes are designed for continuous support and long service life of your critical application.

Holland’s products are used extensively throughout the chemical sector and the widespread application and endorsement of our refractory shapes by this extremely risk-averse industry is further evidence of the performance and consistency of our ISO-Tuff products.

Featured Products

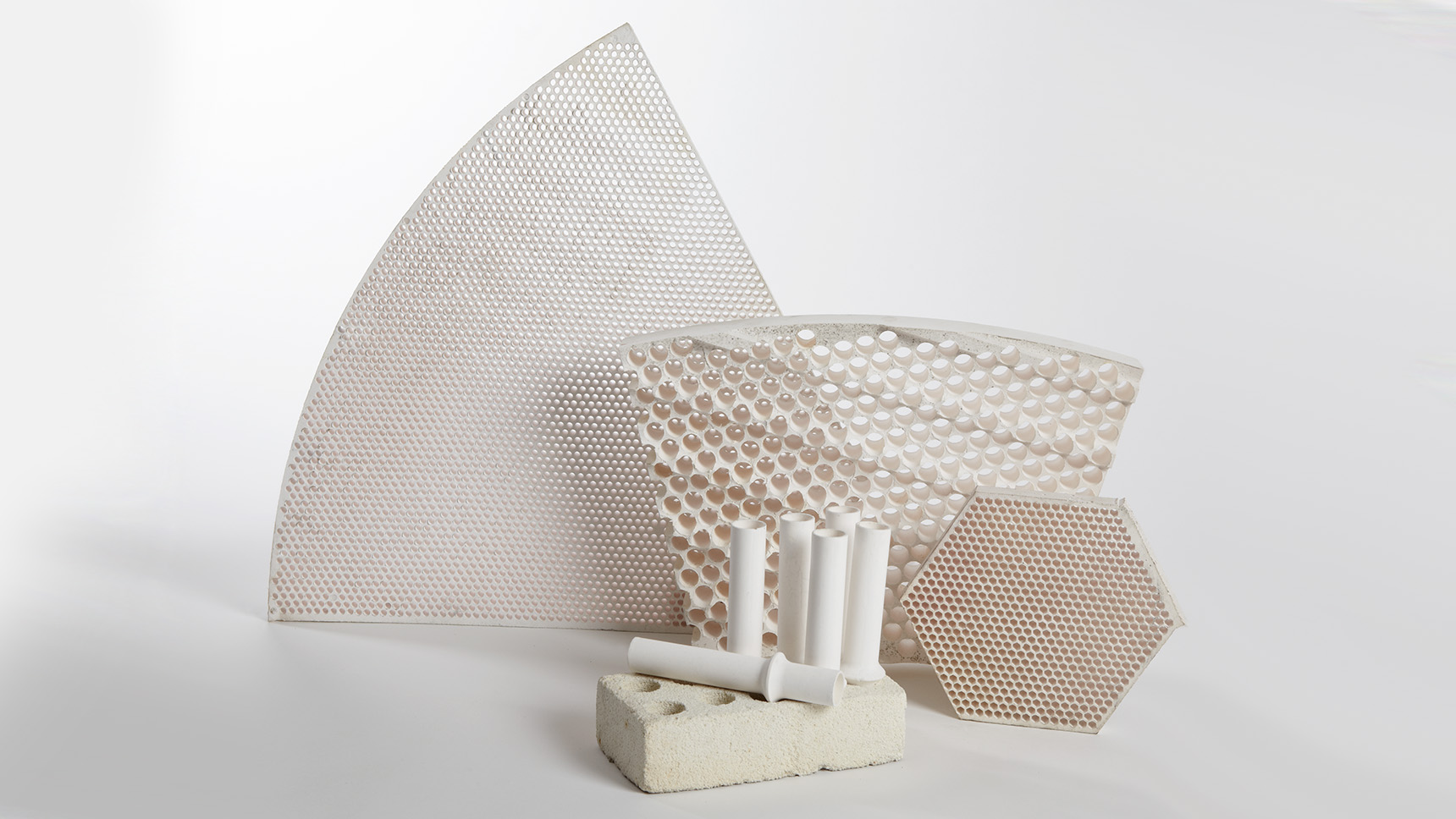

- Catalyst Supports

- Ferrules

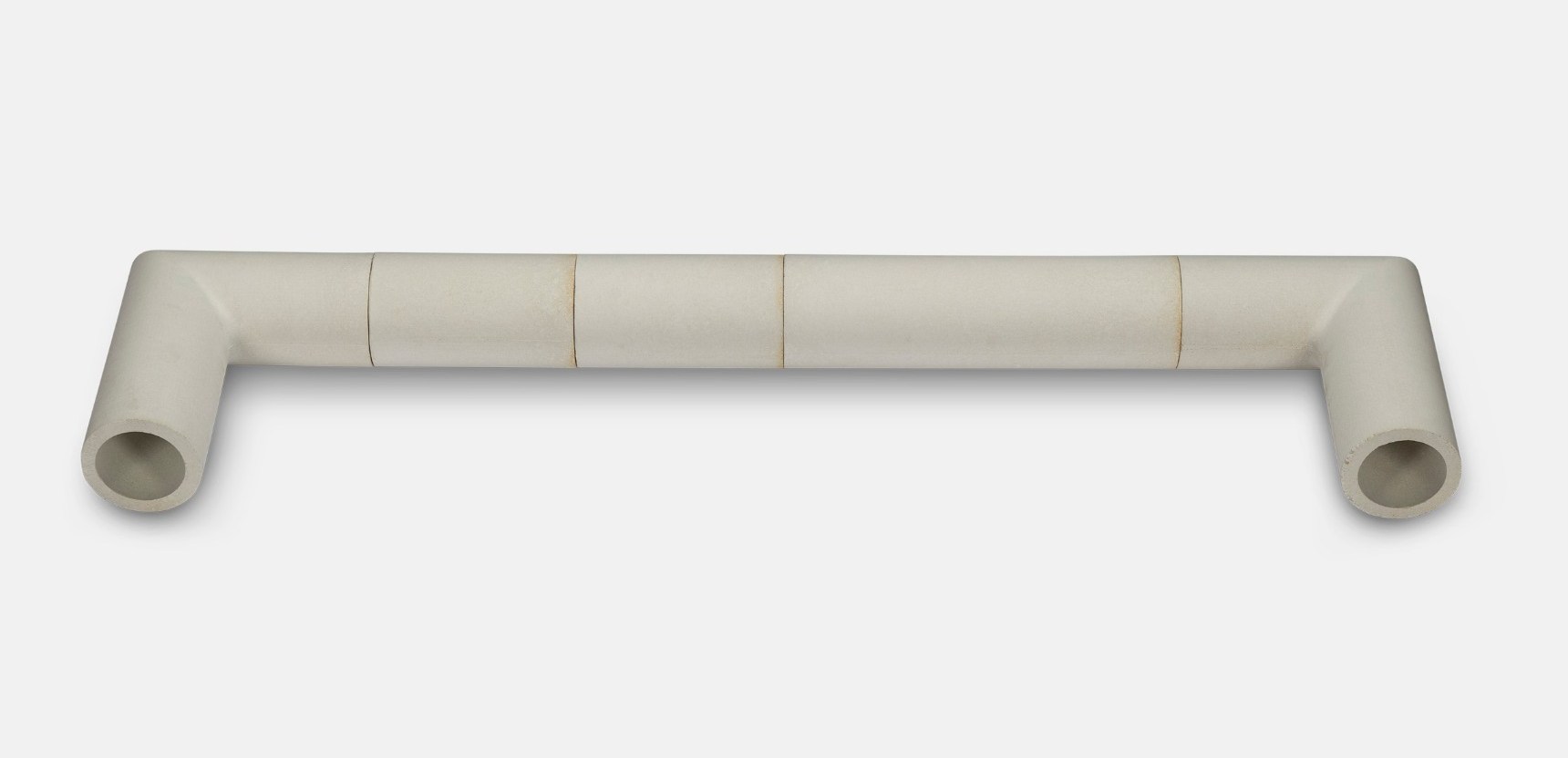

- Gas Nozzles

- Custom Shapes

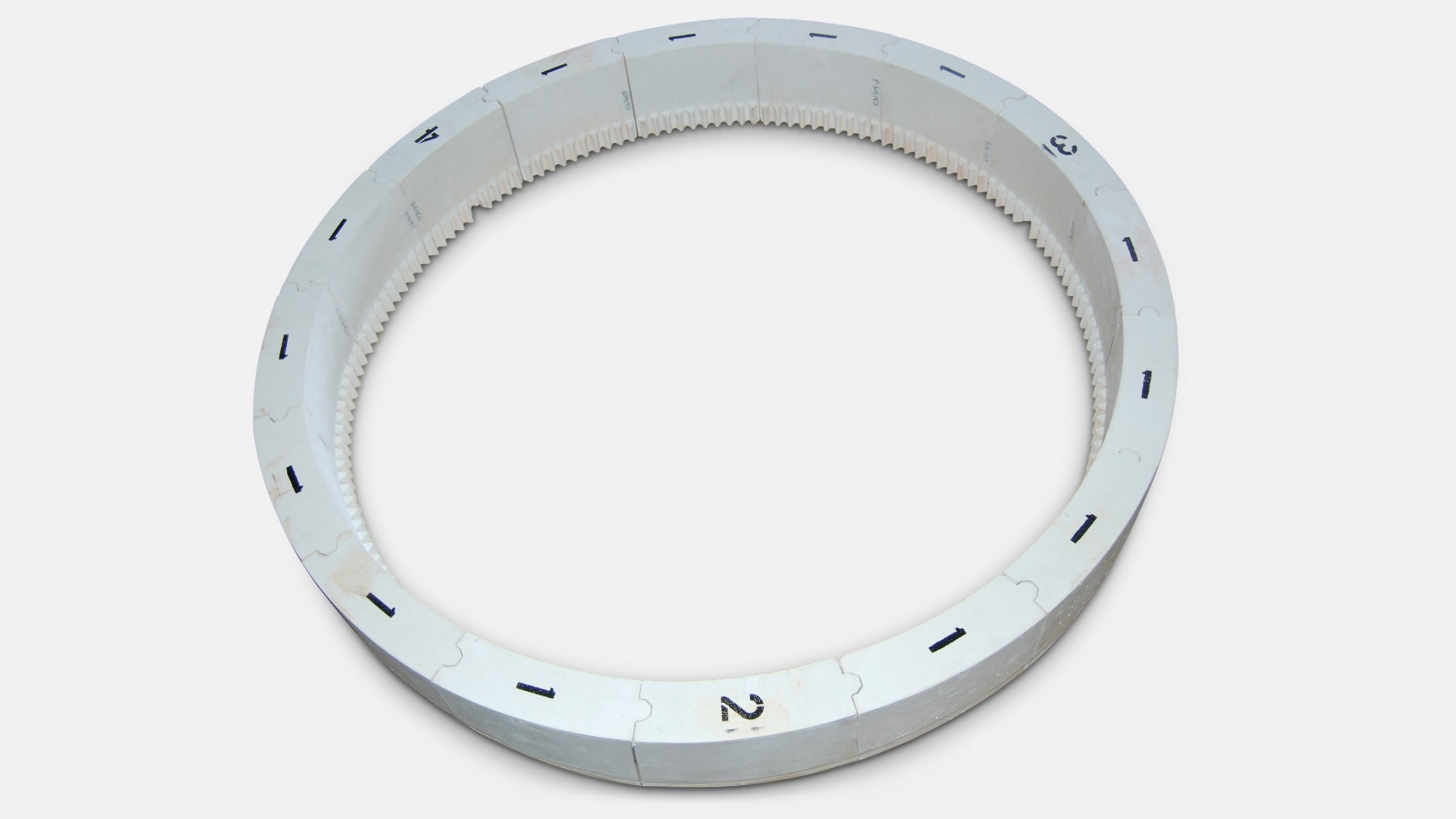

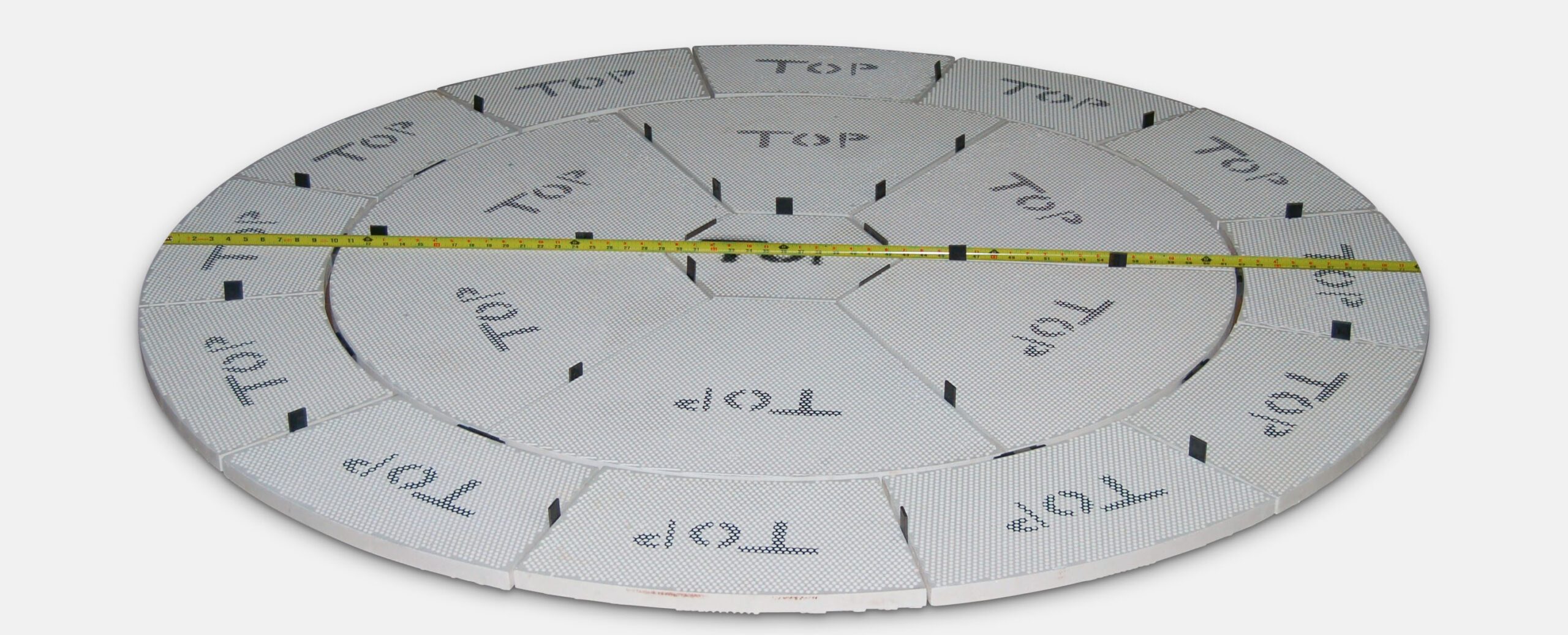

Catalyst Support Systems

Experience heightened productivity with our catalyst support systems, which boast an extended lifespan and reduced contamination levels.

Our versatile high alumina catalyst supports are meticulously engineered to accommodate a wide range of fixed bed reactors, providing you with an oxidation-resistant solution characterized by minimal pressure drop and adaptability to various shapes. Leveraging advanced injection molding technology, we offer unparalleled flexibility to design virtually any shape that aligns precisely with your specifications. Moreover, our extensive selection of materials is geared towards optimizing system longevity and performance, ensuring sustained productivity gains for your operations.

Key Product Characteristics

Chemical Inertness

Minimize contamination with our chemically inert catalyst supports, designed to maintain purity and integrity throughout operation.

Enhanced Durability

Say goodbye to oxidation-related issues as our catalyst supports are engineered for longevity, delivering robust performance and prolonged service life.

Structural Integrity

Built to withstand the rigors of operation, our supports offer exceptional strength to prevent warping and maintain dimensional stability under demanding conditions.

Customizability

Tailor-made to fit your specific application requirements, our supports feature variable hole sizes, web thicknesses, and a diverse array of shapes, ensuring seamless integration and optimal performance.

Minimal Pressure Drop

Maximize efficiency with our supports, which feature very low pressure drop characteristics, facilitating smooth and uninterrupted flow within the reactor system.